Before using HDPE sheet, installation is more important and cannot be ignored, which is also an important prerequisite for improving the wear resistance of HDPE

What is HDPE ? FAQ Guide About HDPE 1.What is High Density Polyethylene(HDPE)? 2.What are the types of HDPE? 3.What are the advantages of HDPE? 4.Is HDPE plasti

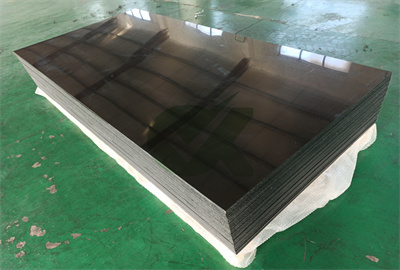

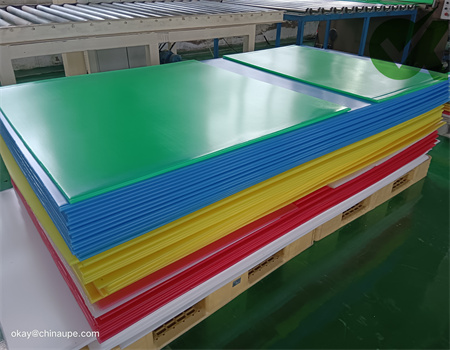

HDPE Sheets are a commonly used petroleum thermoplastic with the best strength/density ratio. Due to its molecular structure, this polymer performs best in applications that require moisture resistance and cost-effectiveness.

.jpg)

The reason polyethylene repels water is because there is no possibility of hydrogen bonding or strong dipole-dipole attraction between the polymer and water. Si

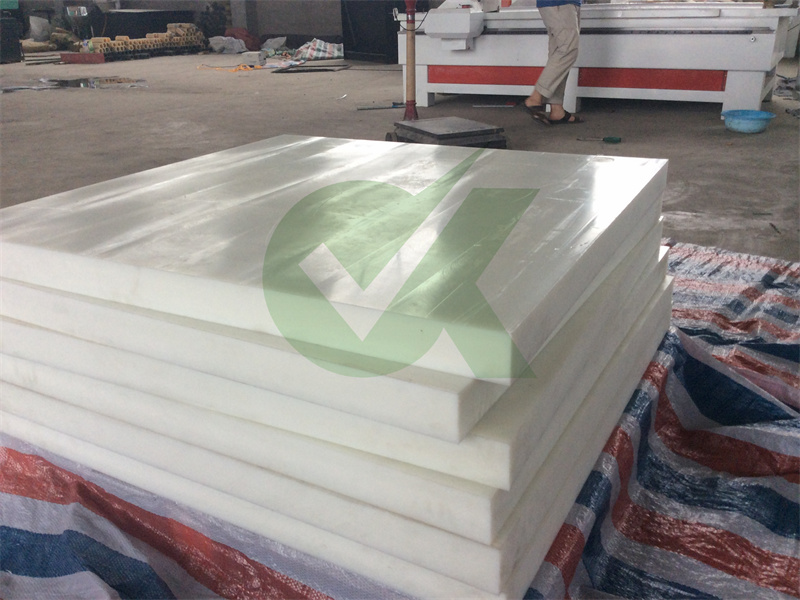

The polymer wear-resistant plate is made of 100% new ultra-high molecular weight polyethylene raw material, and imported wear-resistant agent is added, which gr

.jpg)

Most people are more concerned about this issue no matter what product they purchase. It is undoubtedly very important to purchase cost-effective products.

We a

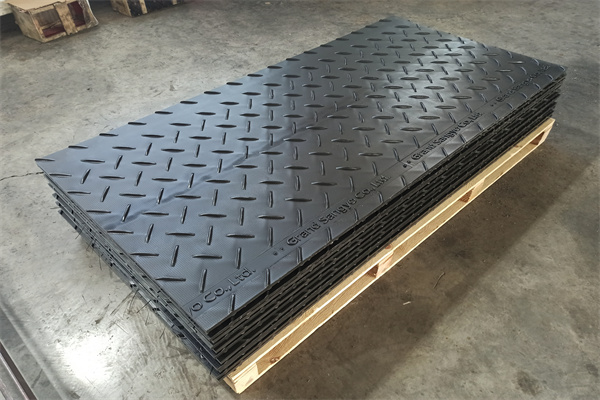

Heavy machinery such as excavators, bulldozers, and trucks often pass or operate on soft ground such as soil and lawn. In order to protect the road surface, law